Track Actuator Analysis Rig

SURI Summer 2023 Project

For this project, I was tasked to create a test rig to test the motor and flexible track characteristics for a bigger research project being done in the Stanford SHAPE Lab. The purpose was to explore the possibility of using active center nodes by discovering tradeoffs between motor torque and curvatures generated. Additional goals included determining the role of boundary conditions on the shapes and curvature generated and to determine if the motors can hold shapes while not powered.

SURI 2023 Final Poster: HERE

Physical Assembly: Track Manipulation

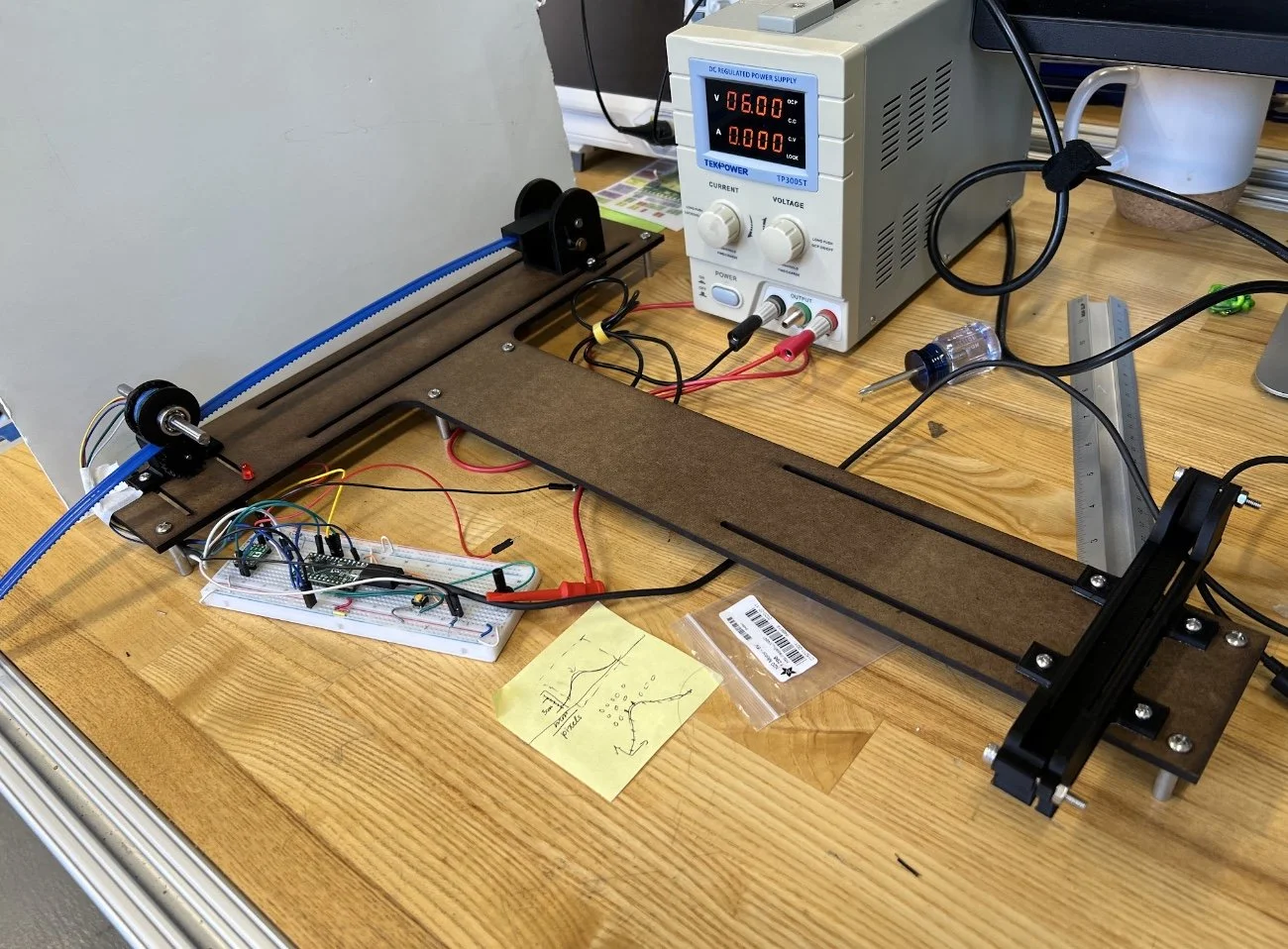

Electromechanical Methods

Circuit design utilizing Teensy LC and shunt resistor to calculate current draw from the motor

Encoder and motor characteristics used to calculate motor RPM and estimate mechanical output torque

State machine used for reliable repetition and ease of use when testing between different boundary condition

Software

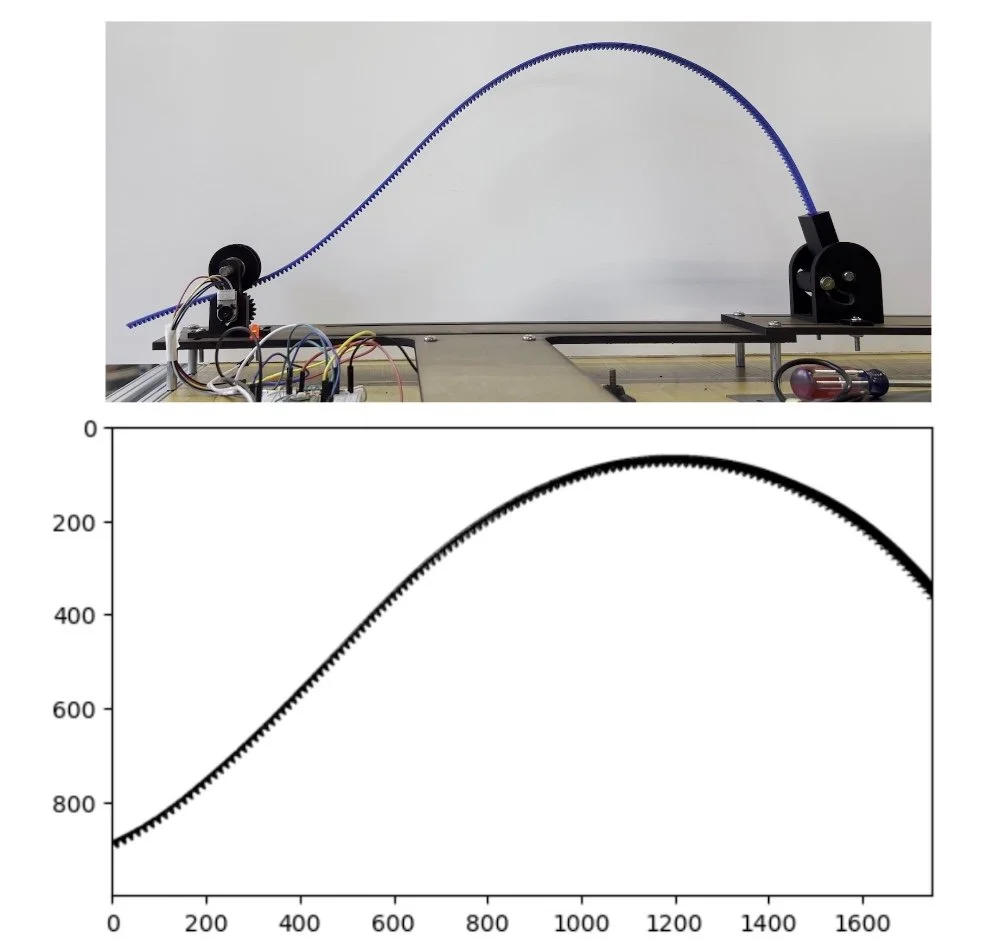

Wrote an image processing script in Python capable of measuring the height and shape and curvature of the track at each frame in the video

Arduino Program operates testing via state machine and records time, voltage, current, torque, work, distance extruded, height, track coordinates. This data is combined with image data to comprise individual test CSV

Matlab script visualizes data from CSV and uses track coordinates to calculate curvature for each frame.

Mechanical Design involved a geared extrusion attachment for the motor to extrude the elastic track horizontally.

Adjustable end piece allows for distance conditions between 250mm and 450mm, and angles between 0 and 90 degrees, or a free pin joint

The test rig involves a rigid connection and an adjustable phone mount to allow repeatable video recording of the test in front of a white backdrop. This allows for reliable and repeatable image processing

3D printed parts for rapid iteration and conformable design

Results

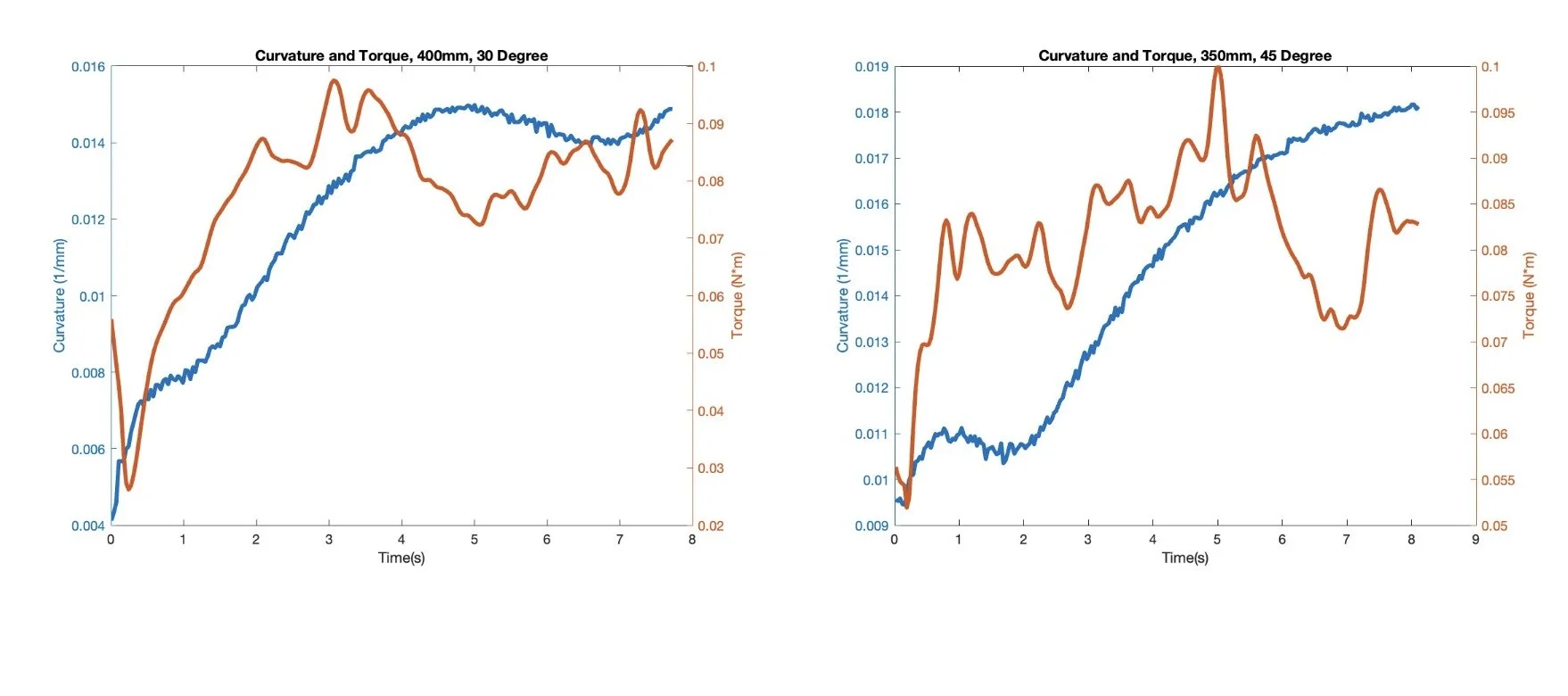

Torque increases as angle decreases, and loosely follows the speed at

which curvature change

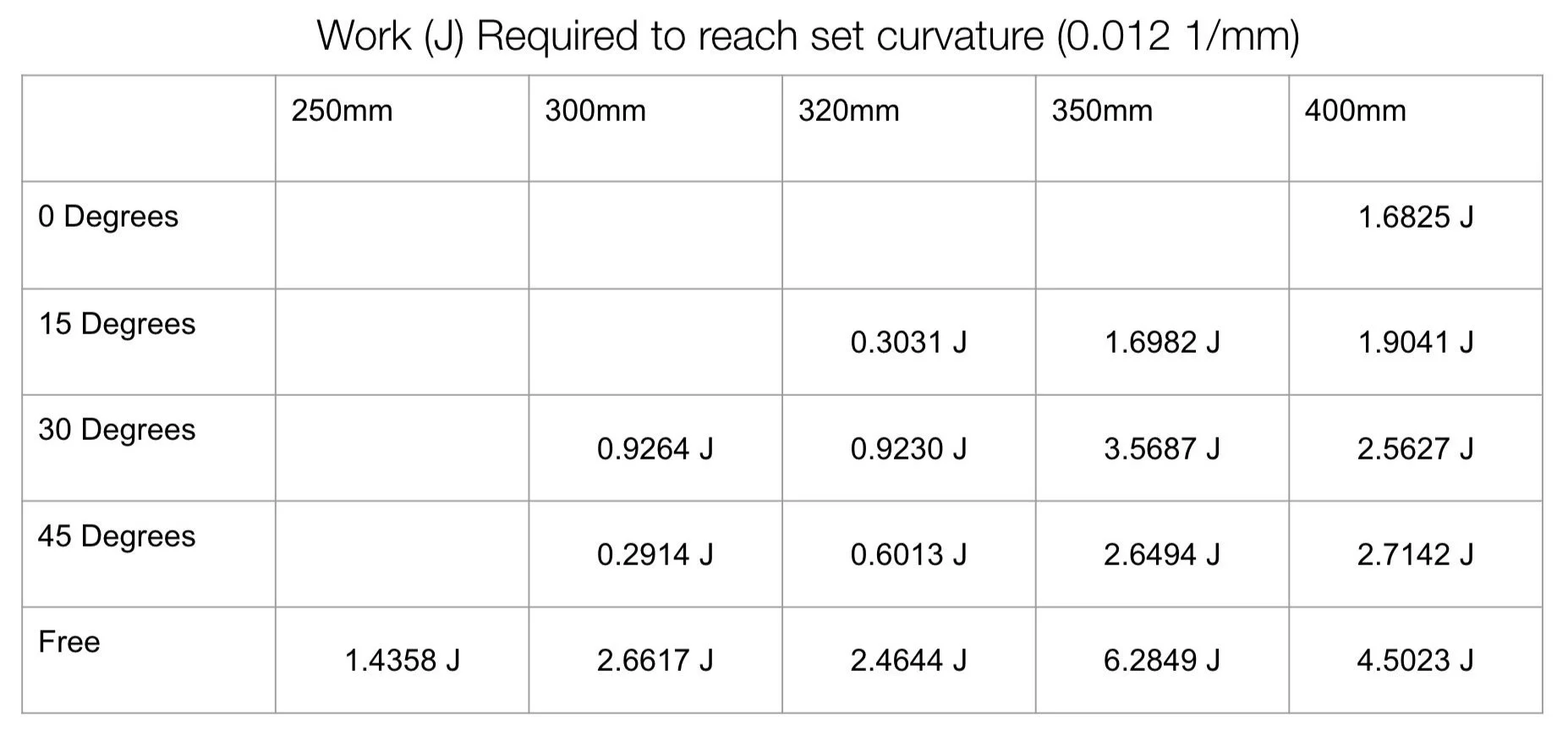

Work increases linearly over time, less dependent on curvature

changes and more dependent on speed to create set curvature

Power Drawn to create certain curvatures dependent on both the

angle and distance of the end condition

More distance = more power

Shallower angle = more power

1:298 gear ratio motors are generating ~0.0275 1/mm curvature

before stalling

Minimum distance to create significant curvature using the tracks

without stalling = 250 mm

Motors held without power under all conditions/curvatures they were

subjected to