“Double Take” Bottle Opener

Design Objective

Prompt: Design and manufacture a bottle opener using the Theme:

“Juxtaposition”

Goals: This was my first CNC project that utilized 3D tool paths, and required multiple CNC’d parts and setups. I wanted to make a personalized bottle opener that was functional, elegant, and visually striking.

Process Story

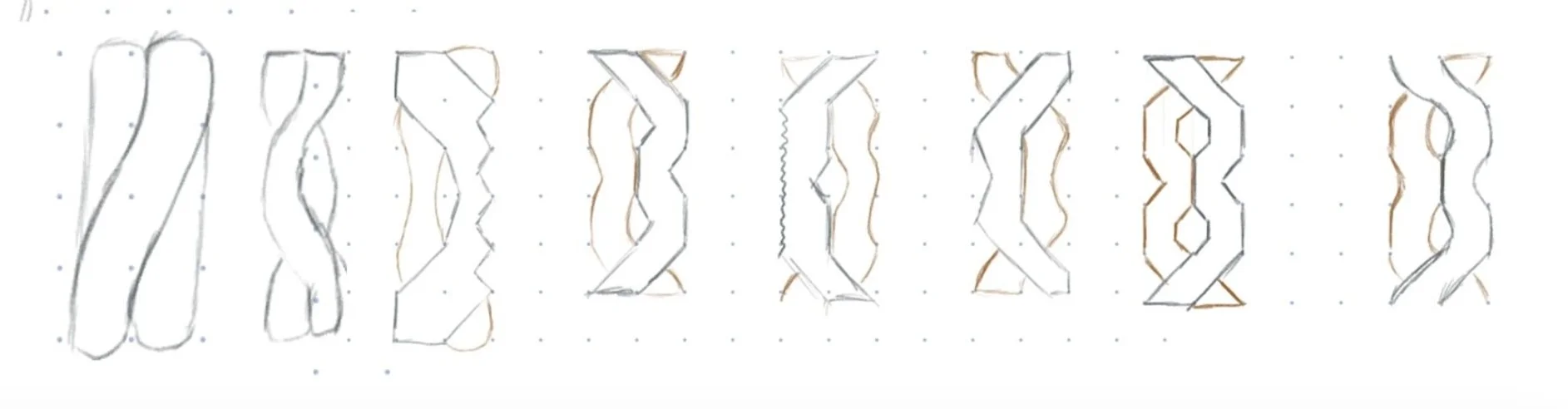

To express the theme of Juxtaposition, I explored multiple elements that eventually came together in the final concept sketches:

Contrast (Material, Color, Accents)

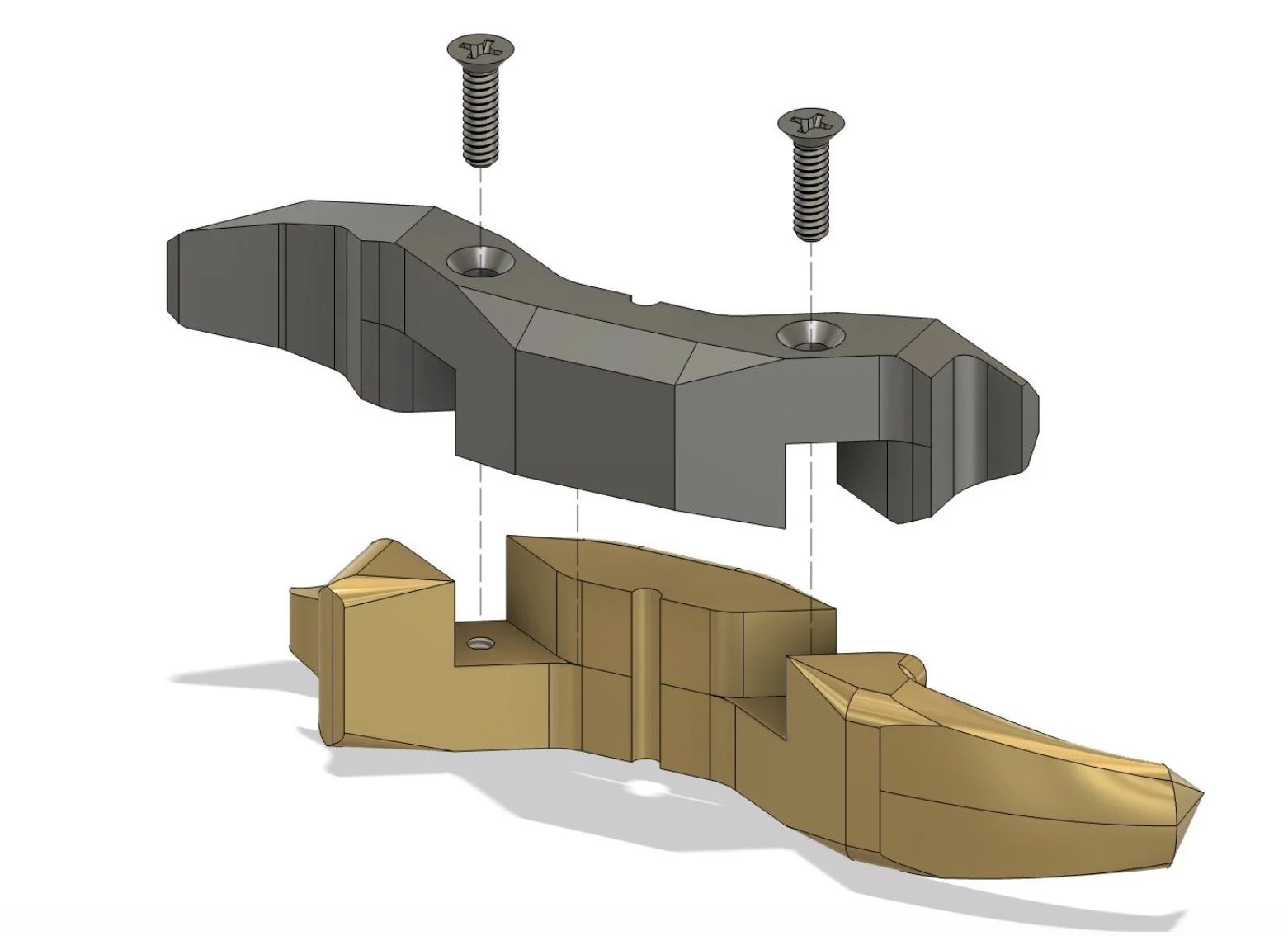

Inversion (Interwoven design, bottle opener & shotgun tool )

2 Halves (linked pieces, each with only half of the tool)

Prototyping

Design Decisions

Key Choices:

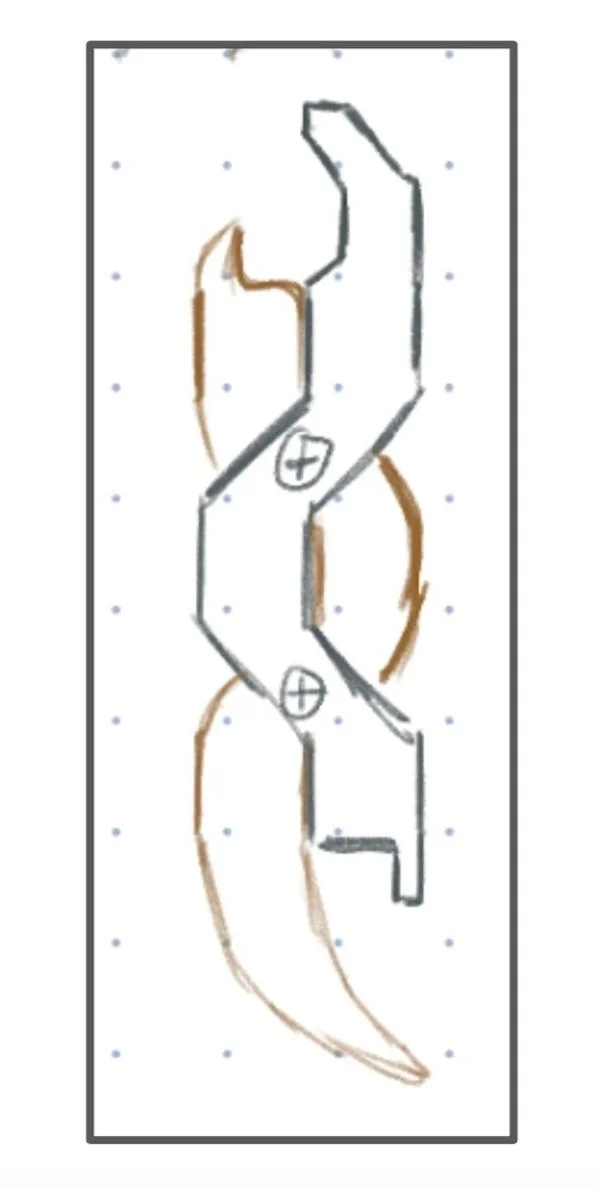

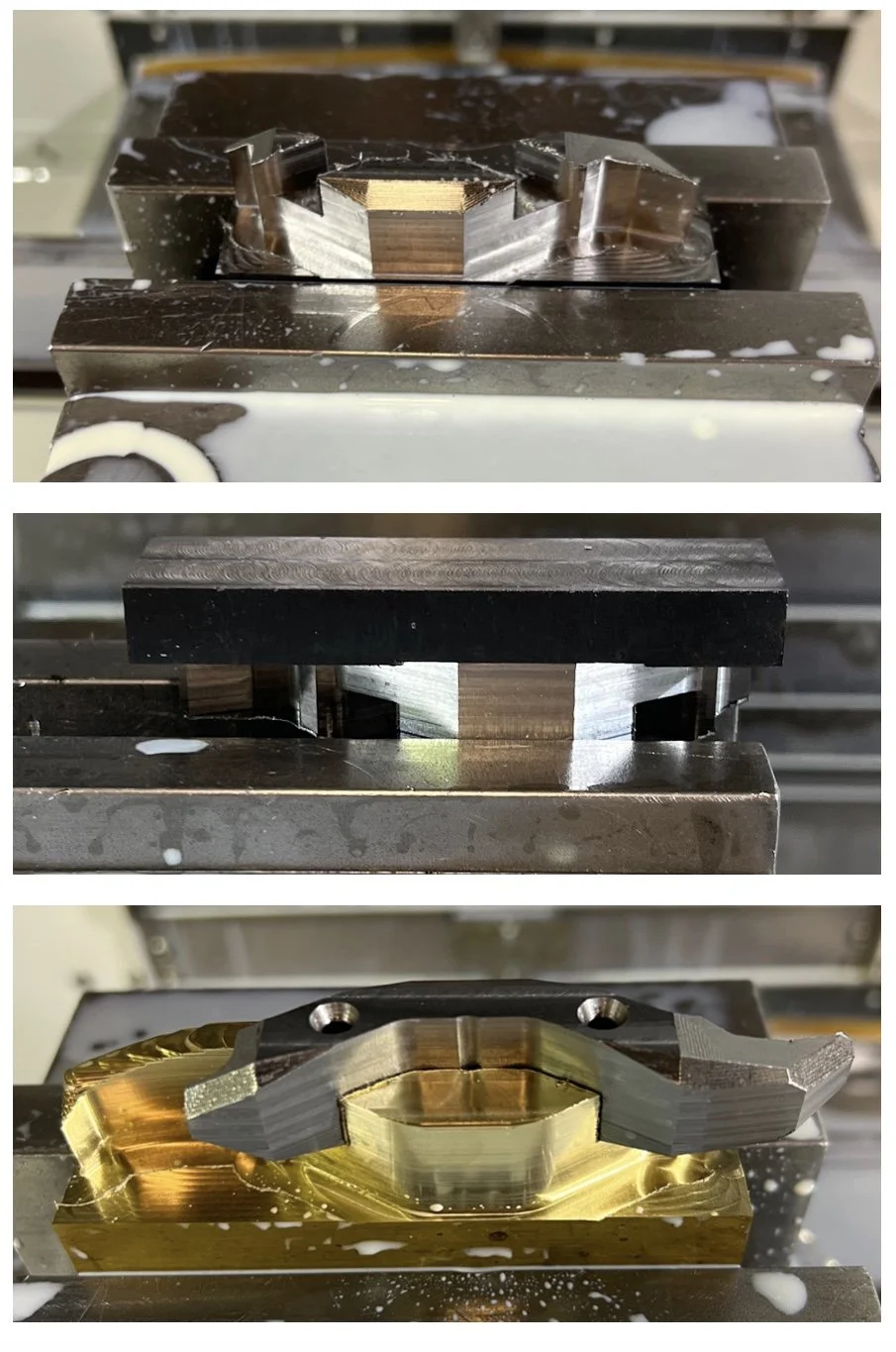

Design to allow for clamp-ring and vise stop as work holding technique

Steel and brass for contrasting materials

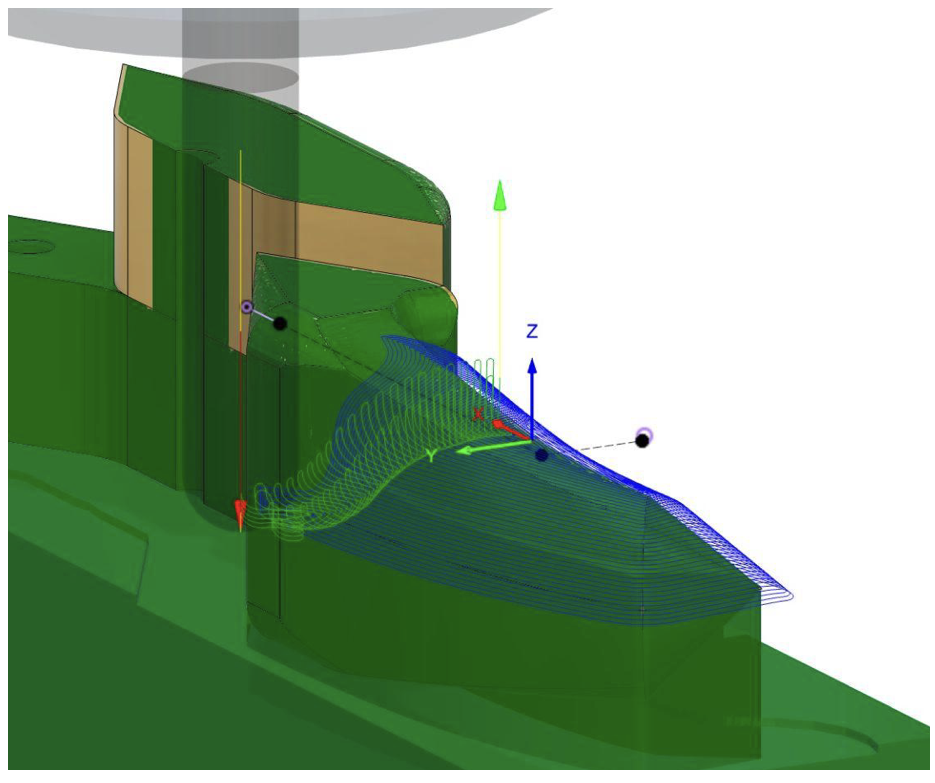

Geodesic tool path for 3D features

Countersink screws for seamless connection

Final Design

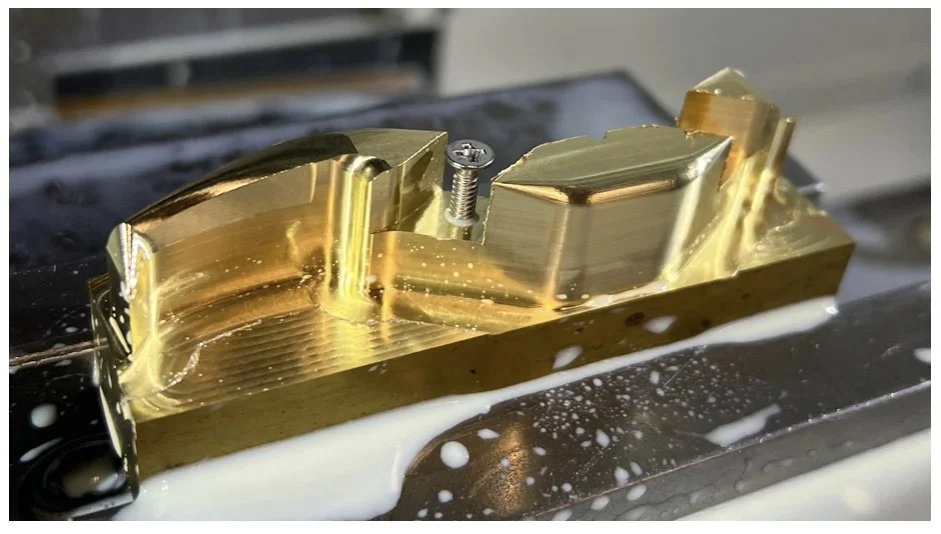

The finishing passes allowed 3D features to come out beautifully and surfaces looked good enough to leave without post-processing. Both tools work without issue and I added a small hole in the center to allow for a keychain connection

Skills Learned

-

During this course I learned about and explored different work-holding techniques like clamp-ring, soft jaws, wax, and tabs. I was able to execute the clamp-ring technique for this product

-

For this project I was able to learn about different 3D tool paths and apply them to my CAM design. I simulated multiple options to find the best path to cut down machine time.

-

I was able to demonstrate finishing tool selection and editing feed rate and speed of tool paths to increase the final quality of the parts